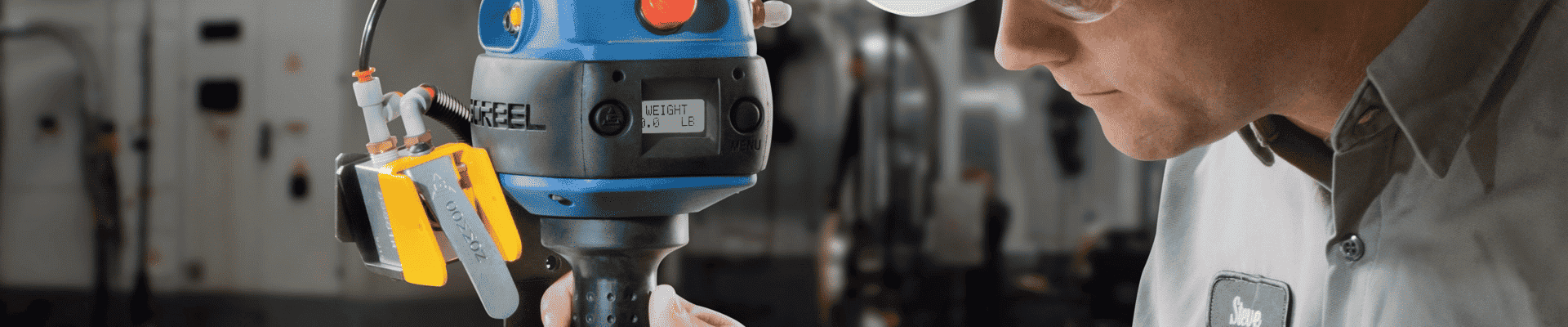

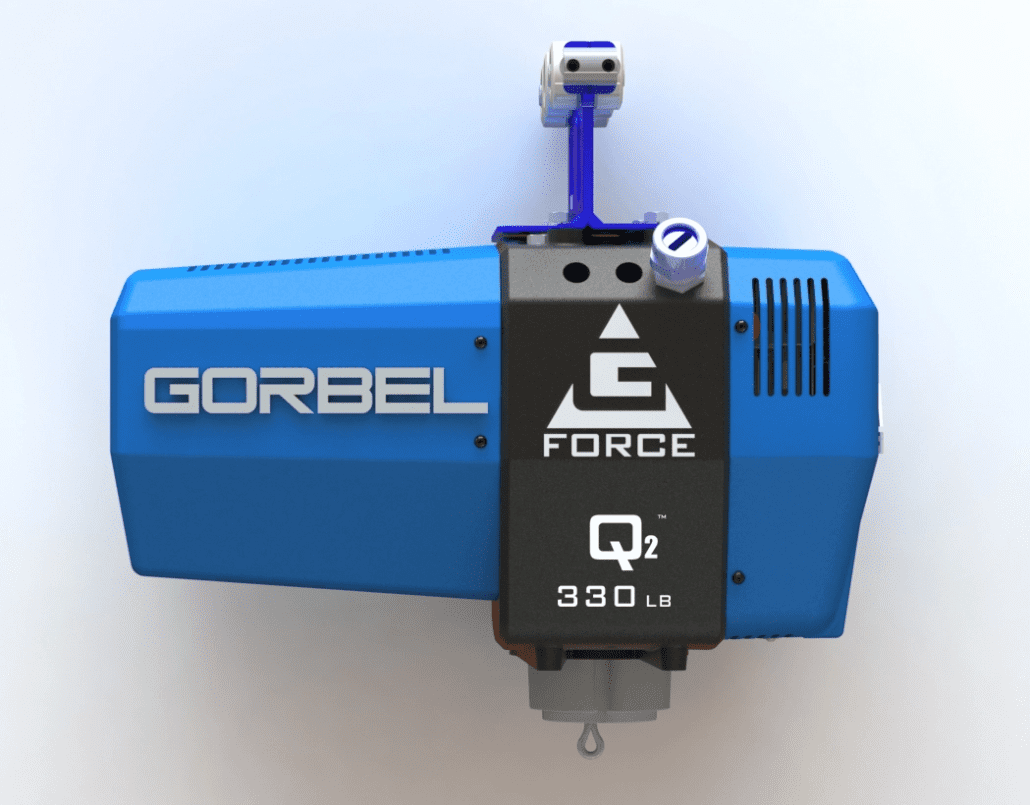

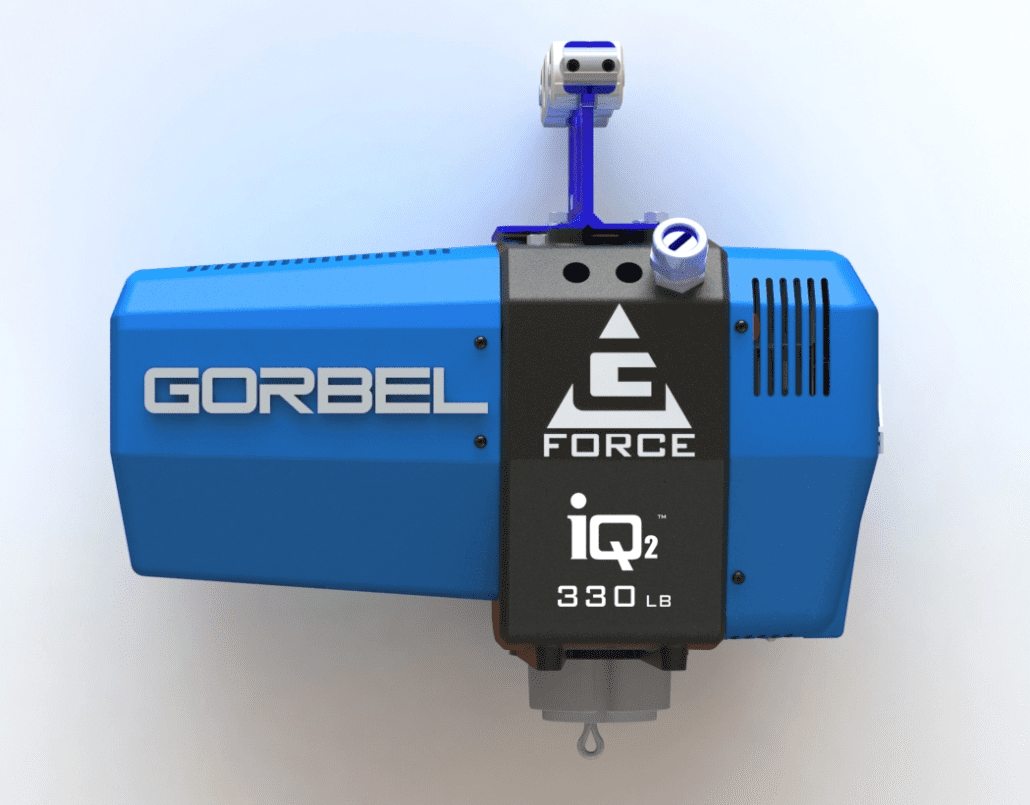

G-Force Intelligent Assist Device

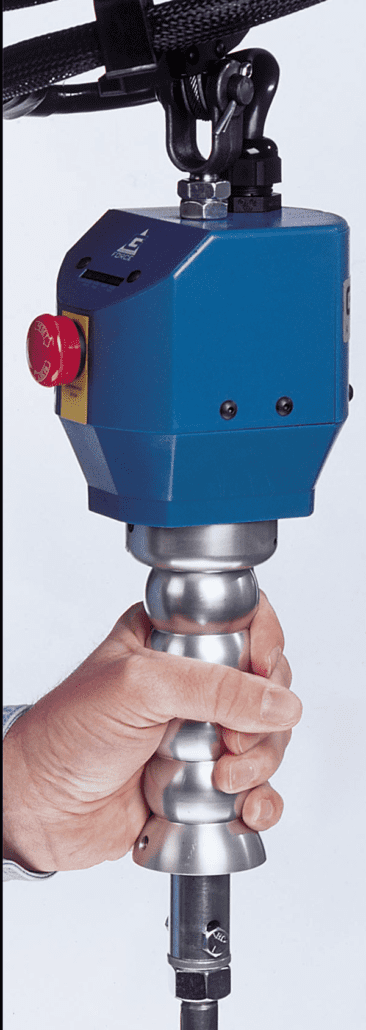

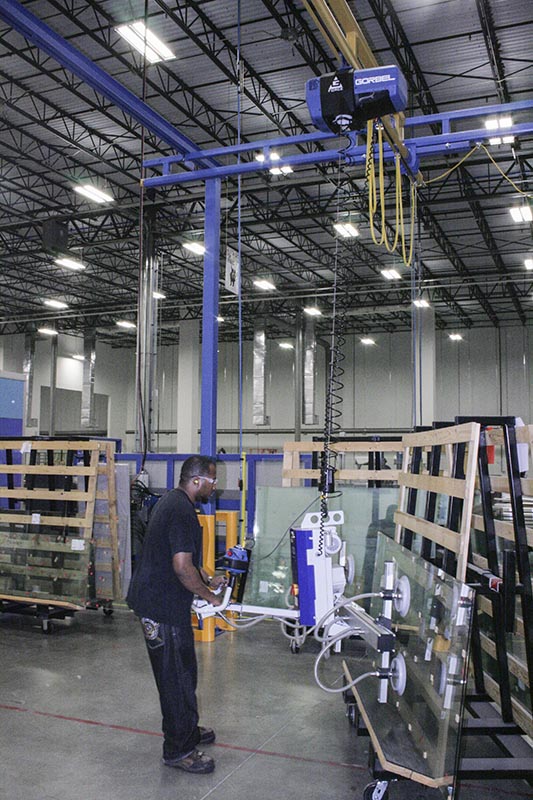

G-Force technology fills the void between traditional lifting devices and completely automated robotic solutions. These devices use the human’s intelligence and adaptability for guidance, but the work is done by the device.

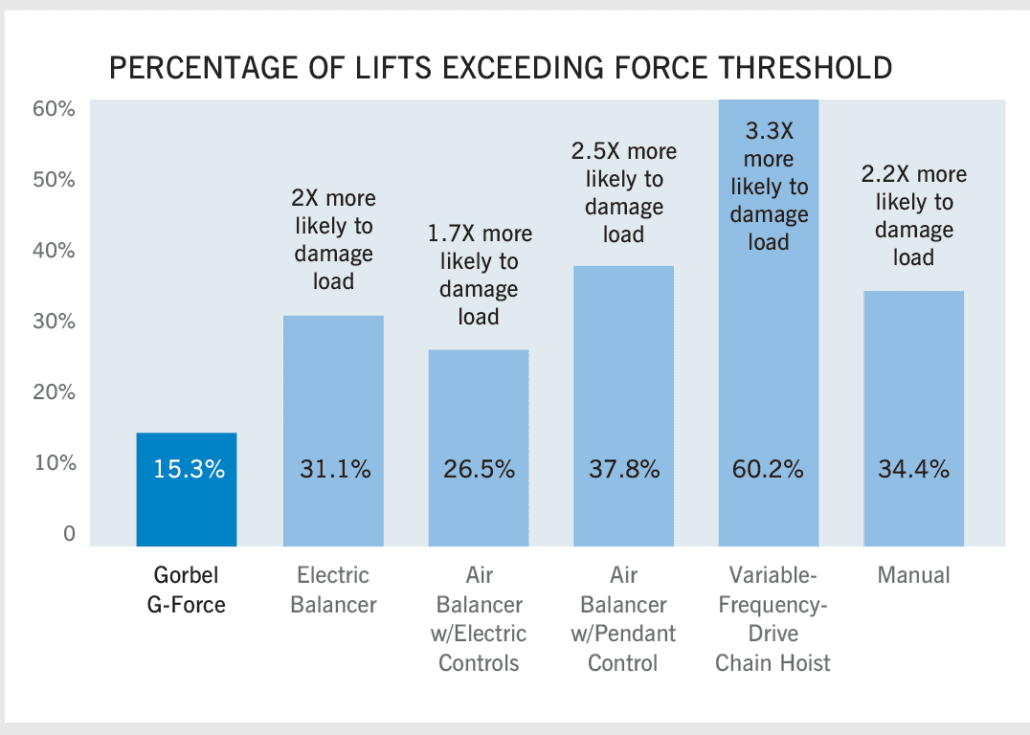

Gorbel’s G-Force Intelligent Lifting Devices use exclusive patented technology and an industrial processor-controlled servo drive system to deliver unmatched lifting precision and speed. Their fusion of advanced technology and basic human guidance maximize your productivity while minimizing the risk of injury to your operators.

Questions?

We’d be happy to talk.