CRANE RUNWAYS

Crane runways are available as free standing, ceiling mounted, or semi-free standing (using existing structure for half the support). The crane runway system you will be able to use depends on the bridge crane you decide on. Though most of our runways work with almost all of our bridges, there are a few that are more selective. Our crane runway systems are fully capable of expansion and include full services and replacement parts.

Questions?

We’d be happy to talk.

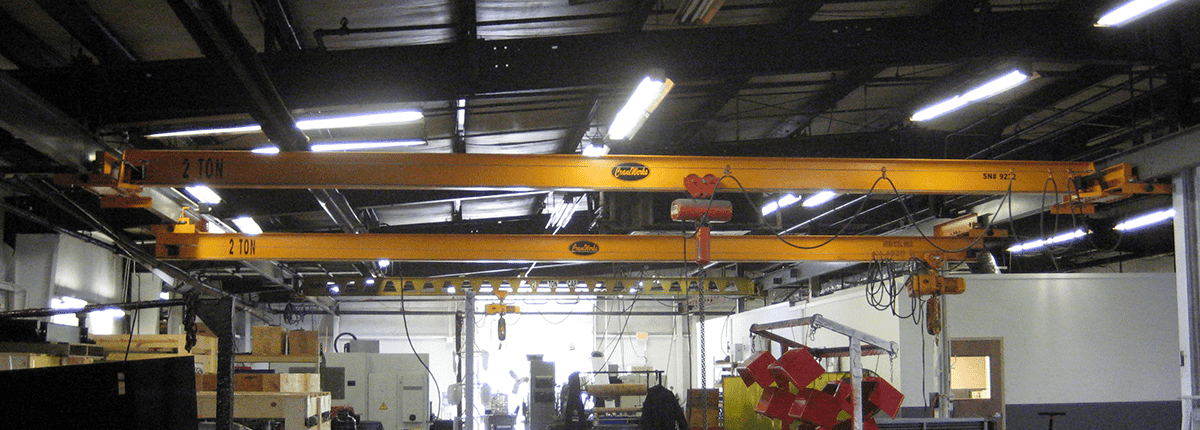

Freestanding Runway

The Freestanding runway stands on its own – its design resists lateral and longitudinal forces unaided. Braces to other support structures simply aren’t necessary. This independence brings versatility: the system’s just as comfortable outdoors as indoors. The bridge crane runs on rails mounted to the top of the runway beams, maximizing the available hook height. Top Running Freestanding bridge crane runways are also able to handle higher capacities than underhung models.

Header-Braced Crane Runway

The runway is supported by the freestanding support columns, each pair tied together by a header. Header-braced systems are ideal when the lowest obstruction in the building is high enough that it does not limit the hook height. This runway type is easily expandable, and can handle multiple bridge crane systems.

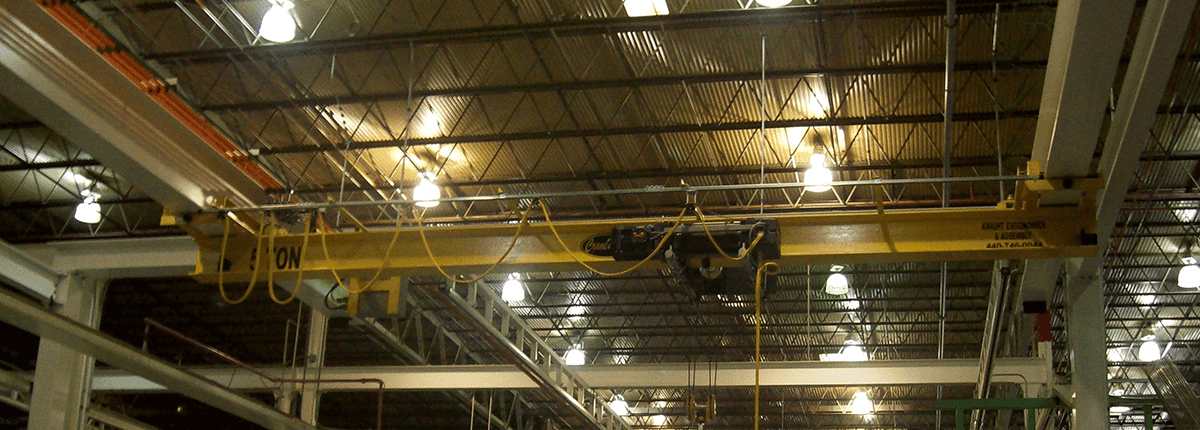

UNDERHUNG CRANE RUNWAYS

Generally a lot lighter than a top running system, underhung crane runways allow for more versatility and usability. Because they’re dramatically lighter, underhung runways can be ceiling-mounted. They also have the ability to run side-by-side without interfering with one another. Another mechanical advantage of underhung crane systems is their ability for multiple systems to be interlocked, enabling operators to transfer loads between them. They can also interlock with monorails, allow for material transfer along a fixed path.

Underhung Freestanding Runway

CraneWerks underhung freestanding runways feature a bolt-together construction which doesn’t require a certified welder for assembly. One of the major advantages of an underhung crane is its ability to interlock with a fixed spur, crossover, and adjacent cranes. This interlocking capability allows a load to be transported throughout the plant system without the need to set it down, thereby eliminating re-handling.