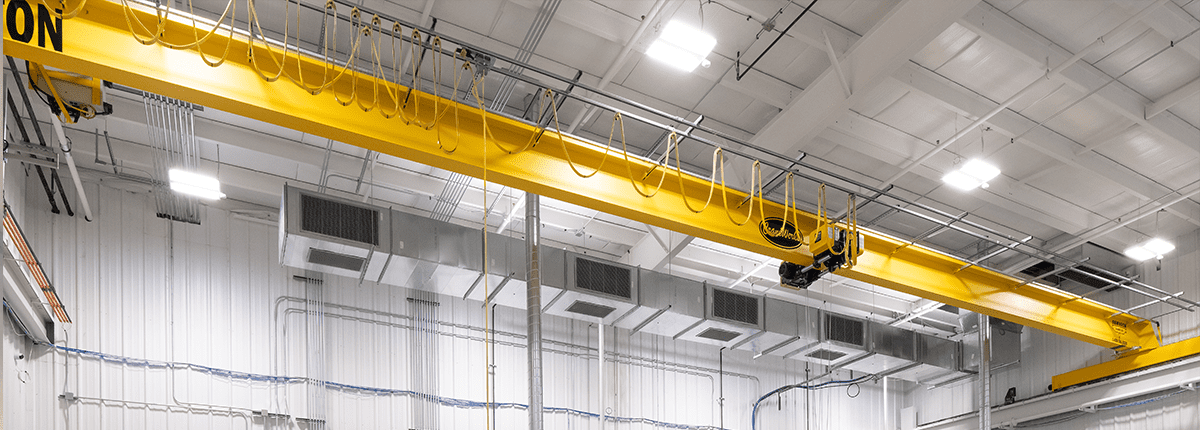

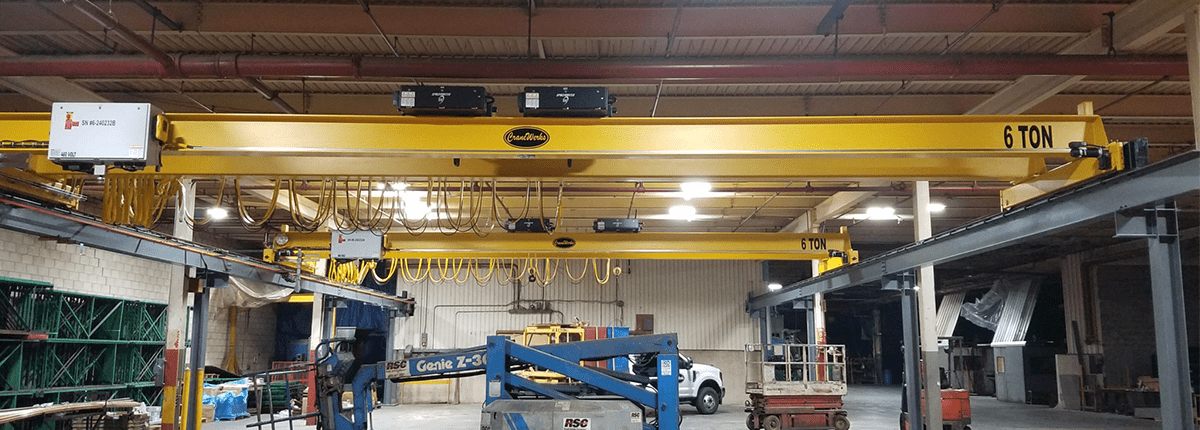

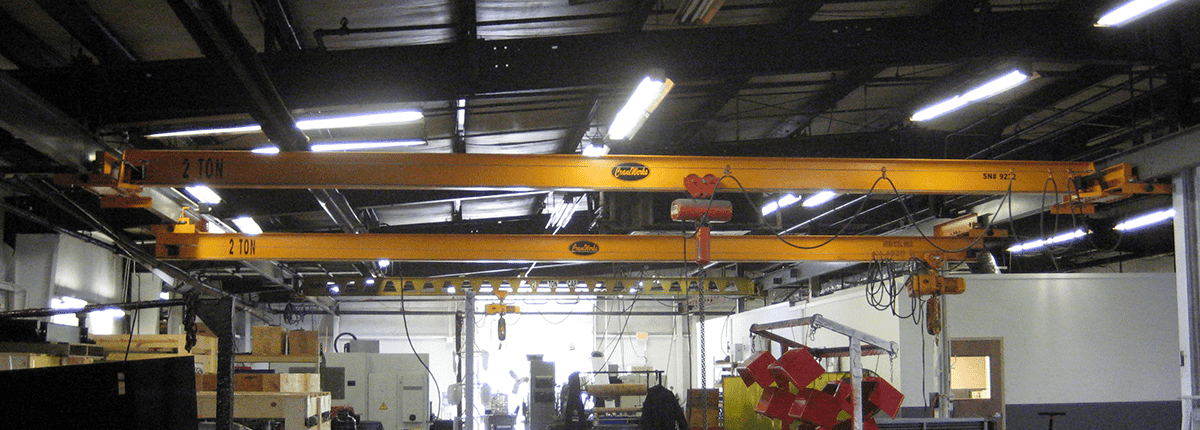

OVERHEAD BRIDGE CRANE

Overhead bridge cranes are designed more for heavier lifting, 20 tons or more. Due to the heavier load, these runways are less flexible. Top running overhead bridge crane runways are good for facilities that have low headroom, because the system moves above the runway. A rail is installed on top of the runway beams, and the wheels ride on the rail rather than directly on the runway beams.

Bridge crane equipment is available with full installation, maintenance, and emergency repair services. We also provide a complete line of replacement or remanufactured parts for all cranes.