MONORAIL CRANES

Service Crane Company design and install monorail cranes. A monorail crane system is a stationary, overhead track on which trolleys travel to carry loads from one place to another in a facility. Monorail cranes are an ideal solution for linear, overhead material handling due to the fact that they enhance production workflow and create a safe and secure work environment.

Questions?

We’d be happy to talk.

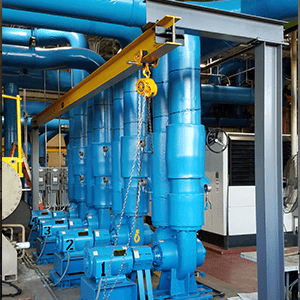

Freestanding Monorail Cranes

- Used in most any environment to perform simple lifting operations from unloading trucks to disassembling dies and other equipment

- Patented track systems are available for monorails with curves and switches allowing material to move from one section of the plant to another.

- Monorail spurs are used for transferring loads from one bridge crane to another or from a bridge crane to another area in the plant.

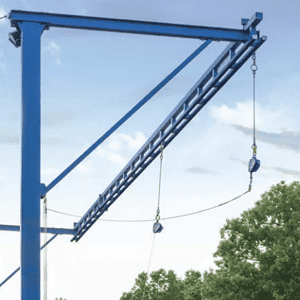

- Free standing monorails can be equipped with a cantilevered beam on one or both ends of the monorail. These cantilevers can be used to reach areas beyond the support columns of the system such as over a pit or dock area.

- Cantilevered supports are also available on free standing monorails when pairs of columns and headers are not possible.

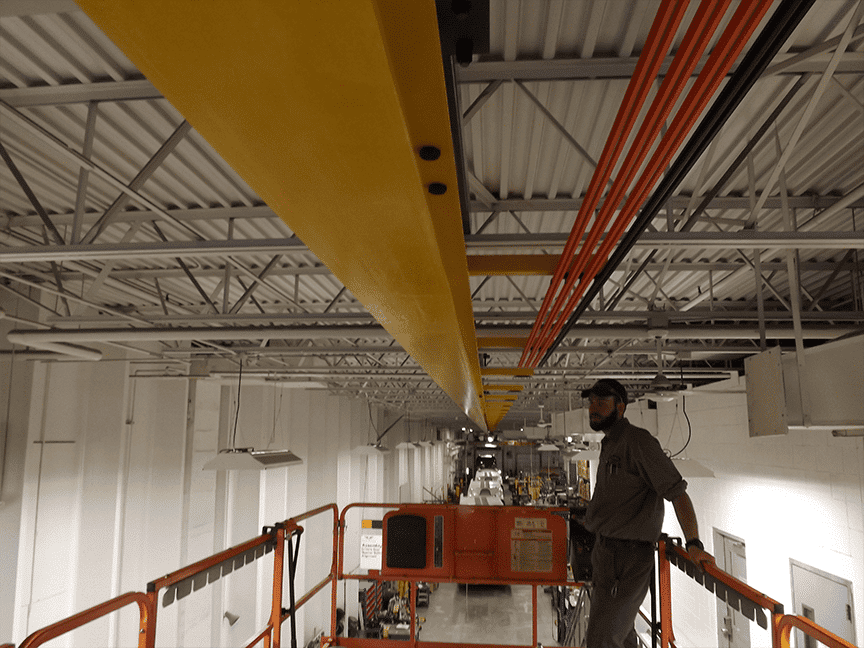

Ceiling Supported Monorail Cranes

Ceiling supported monorail overhead crane systems utilize existing ceiling structures eliminating the need to install columns that create obstructions in valuable production space. One important thing to consider when looking at ceiling mounted monorails is the reserve capacity of the ceiling structure. Service Crane engineering services can aid you in determining the reserve capacity of your existing ceiling as well as other structures to determine if a ceiling mounted monorail industrial crane is right for the application.

-

- Economical way of manipulating small to large loads.

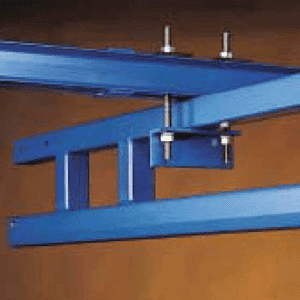

- Bolt together construction for easy installation (can be relocated and added onto as needed)

- Typical capacities range between ¼ and 10 Ton

- Capacities over 2 ton and/or monorails utilizing motorized trolleys are constructed from structural steel or patented track

- Capacities from 250lbs to 2 ton are available in enclosed rail. This is most practical when push type trolleys can be utilized.

Gorbel Enclosed Track Monorail Cranes

Think of this monorail system as an enclosed assembly line. Imagine how a garage door opener opens and closes a heavy door by moving the hoist along one track. However, the hoist does not move vertically or side to side. The door rolls down to the ground along the outer rails of its own track. A linear track is perfect for an assembly line in which parts will be added or adjusted in a controlled sequence. Here are some key features of our Monorail system:

-

- Choose the design. We can design the monorail (enclosed track) to be an overhead designa free standing design or with mixed support styles. It’s necessary to consult with our customer service department on your facility’s exact needs.

- Sturdy structure. The modular structure of the monorail is manufactured from aluminum or steel to provide the adaptability to fit your operational environment. Monorails are ideal for usage in tight or constricted workflow areas or transferring material between areas.

- Hoisting with confidence. Along the enclosed track, the hoist can support a load of up to 4,000 pounds. Depending upon your material handling needs, monorails can be operated manually or with motorization.

- Easy to assemble and dismantle. Any automated manufacturing or loading process needs a rigid structure that will sustain the heaviest load time after time. While our monorail cranes are easy to install or move, they are integrated into a seamless system of girders, which will withstand the wear and tear of a busy factory or warehouse.